Technical Articles

NANBEI Is Professional On Providing One-step Solution Of Laboratory Instruments And Equipment

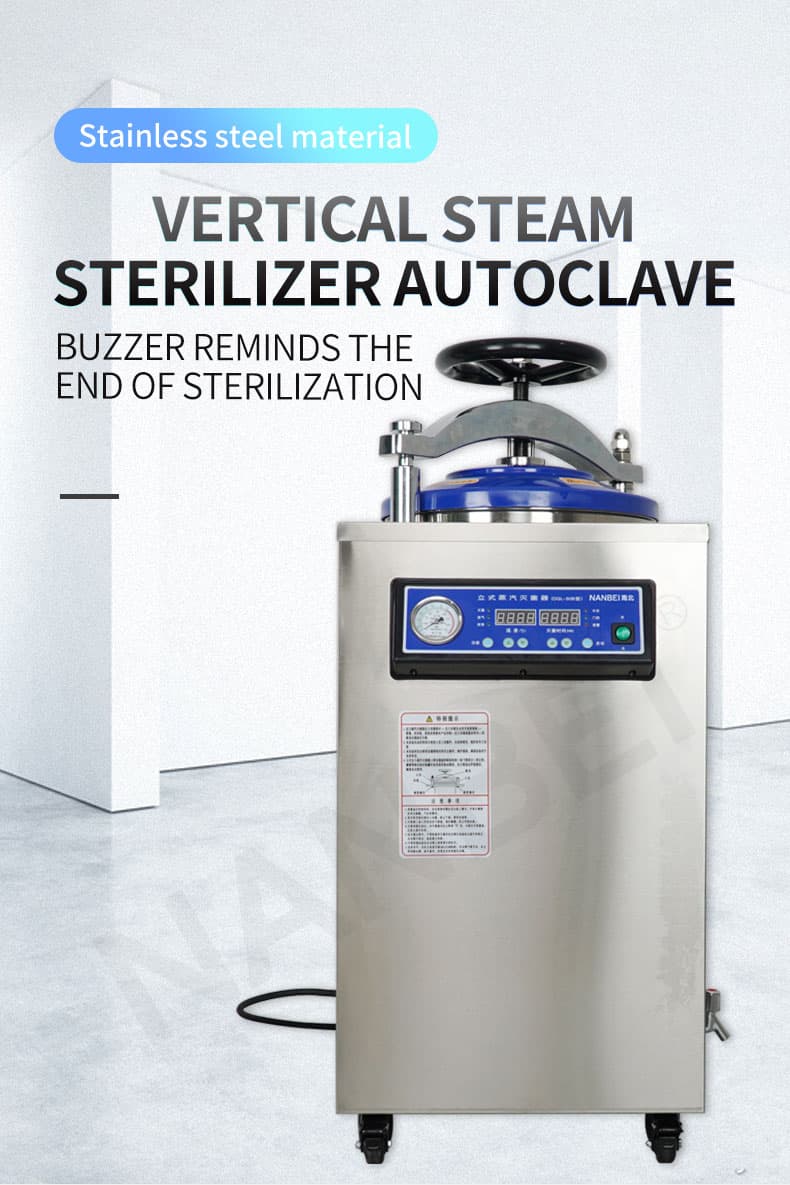

The Automatic Vertical Pressure Steam Sterilizer, commonly known as an Autoclave, is a critical piece of sterilization equipment used in laboratories, healthcare facilities, and other settings to effectively kill microorganisms using steam under pressure. Proper autoclave operation, adherence to safety precautions, and regular maintenance are essential for ensuring effective sterilization, equipment longevity, and user safety.

How to Use Your Automatic Vertical Autoclave

Following the correct procedure is vital for successful steam sterilization.

Preparation:

Ensure the sterilizer is connected to a suitable power source.

Check that the water level in the chamber or reservoir is adequate (use distilled or deionized water as recommended by the manufacturer to prevent mineral buildup).

Properly prepare items for sterilization: clean them thoroughly, wrap instruments or porous materials in appropriate sterilization pouches or wraps, and ensure containers are compatible with high heat and pressure. Understanding steam sterilization principles helps in preparation.

Loading the Chamber:

Place items in a way that allows steam to circulate freely around them. Do not overpack the chamber.

Use trays or baskets provided with the vertical autoclave.

Ensure containers with liquids are not completely sealed to prevent bursting.

Closing the Lid:

Carefully close the lid and secure it according to the manufacturer's instructions. This usually involves aligning markings and turning a locking mechanism until it's tightly sealed to withstand pressure.

Setting Parameters:

Select the appropriate sterilization cycle based on the type of items being sterilized. Common cycles involve specific temperatures (e.g., 121°C or 134°C) and sterilization times (e.g., 15-30 minutes).

Most automatic vertical pressure steam sterilizer models have pre-set cycles or allow custom programming. Refer to your manual for guidance on specific items.

Starting the Cycle:

Press the start button. The unit will typically fill with steam (if it has a separate steam generator), heat up, hold the temperature and pressure for the set time, and then cool down or vent.

Post-Cycle Procedure:

Once the cycle is complete and the pressure has fully returned to zero, carefully open the lid.

Be aware of residual steam escaping, which can cause severe burns. Use heat-resistant gloves.

Allow items to cool before handling or removing them, especially liquids, which can be superheated.

Important Precautions for Sterilizer Use

Safety must be the top priority when operating a pressure steam sterilizer.

Steam and Pressure Hazards: Always wait until the pressure gauge reads zero and the chamber has cooled sufficiently before attempting to open the lid. Escaping steam is invisible and can cause instant, severe burns.

Proper Loading: Never sterilize sealed containers holding liquids or chemicals that could become volatile or explosive under heat and pressure. Ensure all materials are compatible with steam sterilization.

Electrical Safety: Ensure the unit is properly grounded and the power cord is in good condition. Avoid using in wet environments unless the unit is specifically designed for it.

Ventilation: Place the autoclave in a well-ventilated area to dissipate heat and steam.

Monitoring: Do not leave the unit unattended during critical phases of the cycle, especially during pressure buildup and release.

Emergency Procedures: Know the location of emergency stops and understand how to safely power off the unit if necessary.

Training: Only trained and authorized personnel should operate the automatic vertical pressure steam sterilizer. Proper sterilizer use requires knowledge and experience.

Maintenance Guide for Automatic Vertical Autoclave

Regular autoclave maintenance is crucial for reliable performance, preventing breakdowns, and ensuring effective sterilization.

Regular Cleaning:

Clean the inner chamber, trays, and racks regularly to remove residue from water or sterilized items.

Wipe down the exterior.

Clean the door seal/gasket according to the manufacturer's instructions to ensure a tight seal.

Water Quality: Consistently use the recommended type of water (distilled or deionized water). Tap water contains minerals that will cause scale buildup, reducing efficiency and potentially damaging components like heating elements and valves.

Check Seals and Gaskets: Inspect the door seal and any valve seals regularly for signs of wear, cracking, or damage. Replace them as needed to prevent steam leaks and maintain pressure.

Valve Checks: Periodically check the safety valve and steam release valve to ensure they are not blocked and are functioning correctly. The safety valve is a critical safety feature.

Filter Maintenance: Clean or replace any filters (e.g., air filters, water filters) as specified in the manual.

Calibration and Validation: Regularly calibrate temperature and pressure gauges. Perform biological or chemical indicator tests to validate that sterilization cycles are effectively killing microorganisms. This confirms effective sterilization.

Scheduled Professional Service: Adhere to the manufacturer's recommended schedule for professional inspection and service. Trained technicians can check internal components, recalibrate sensors, and identify potential issues before they cause problems. For technical support or service, contact us . Investing in routine professional autoclave maintenance extends the lifespan of your sterilization equipment.

Conclusion

Operating an Automatic Vertical Pressure Steam Sterilizer safely and effectively requires understanding the proper usage procedures, strictly following sterilizer precautions, and committing to regular autoclave maintenance. By prioritizing these aspects, users can ensure reliable steam sterilization results, protect personnel from hazards, and maximize the operational life of this essential laboratory and medical equipment. Learn more about selecting the right sterilization equipment for your needs.