Technical Articles

NANBEI Is Professional On Providing One-step Solution Of Laboratory Instruments And Equipment

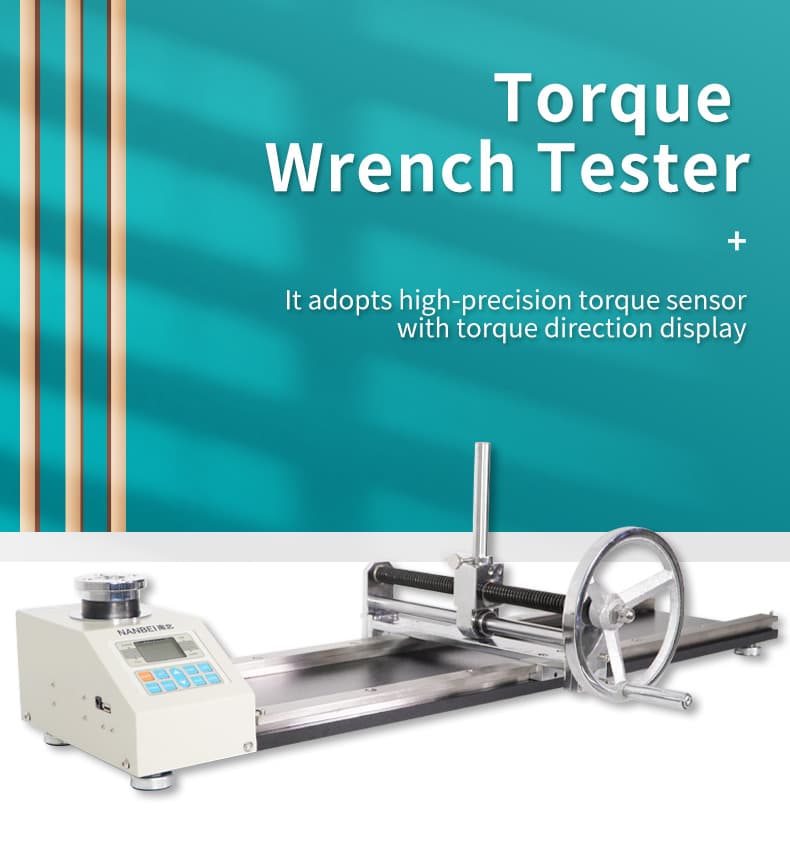

The torque wrench tester can be used to test or calibrate the torque of the torque wrench. It is a special equipment for testing torque wrenches and torque screwdrivers, and is mainly used to test various fixed-force torque wrenches, digital torque wrenches, preset torque wrenches, etc.

To keep the measurement accuracy of the torque wrench calibrator, the following points should be noted during use:

1. Do not use a torque that exceeds the maximum load torque allowed by the torque wrench calibrator to avoid damaging the instrument;

2. Do not knock or place heavy objects on the display panel of the torque wrench calibrator;

3. It is very sensitive to environmental conditions and should avoid using the torque wrench calibrator in the following places:

① Places with splashes of water, oil or other liquids and covered by aerosols with high pH;

② Places with dust, hot air, and vibration;

③ Outdoors or in places with discharge phenomena;

④ Places with high humidity or high temperature environments

⑤ Places under electromagnetic interference working environment conditions;

⑥ Any other places that may cause functional failure or precision distortion;

4. Do not open the back cover to calibrate various components;

5. Do not loosen the screws that fix the test head, as this will reduce the resolution;

6. Do not store the torque wrench calibrator in places with high humidity or high cold, as this will easily cause water droplets to condense inside the instrument and degrade its function.

When using a digital torque wrench tester, avoid shock and vibration during the test to avoid affecting the test results. Use the correct wrench model and range to avoid damaging the equipment. Regularly maintain and calibrate the tester to ensure its accuracy.