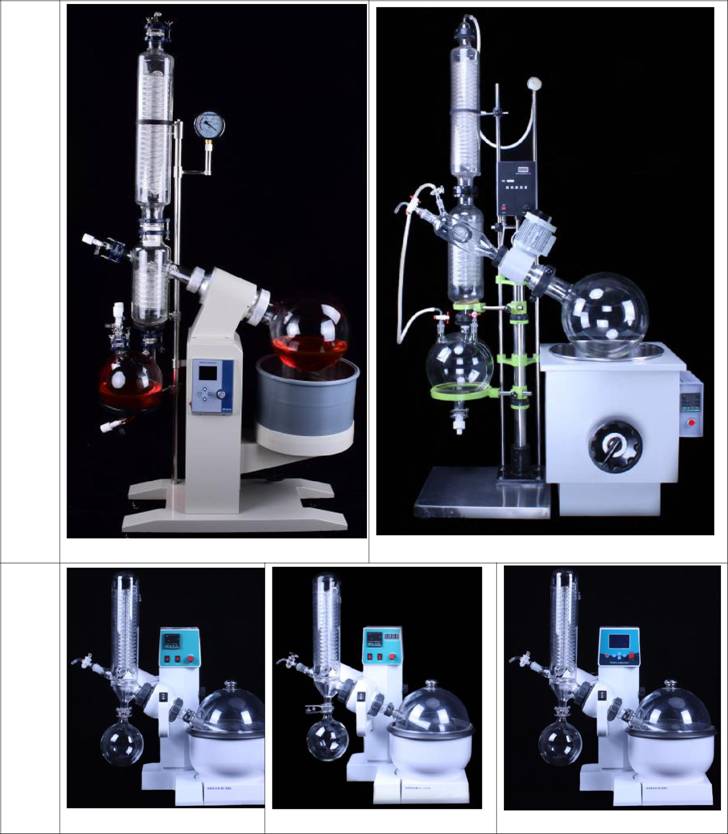

Brand:NANBEI

Model:

Application:Ideal for chemical, pharmaceutical, and research labs, Nanbei rotary evaporators ensure safe, fast, and reliable solvent recovery during distillation processes.

NBRE-201D/NBRE-301/NBRE-501 2L 3L 5L

1. Using PTFE and fluorine rubber compound sealing to maintain a high vacuum degree.

2. It adopts high-efficiency condenser to ensure high recovery rate.

3. Feeding continuous.

4. Water bath with digital and continuous temperature controlling.

5. Reasonable structure, special materials . The mechanical structure mainly use stainless steel and aluminum alloy parts, glass pieces are all made of high temperature resistant and high boron glass. Imported Electrical key-module. Rubber seal is easy to adopt the new international, making it easy for users to purchase and update.

6. B type, E type is equipped with speed indicator, it can accurately display rotation speed, E type is LCD screens.

| Model | NBRE-201D | NBRE-301 | NBRE-501 |

| Glass meterial | GG-17 | ||

| Holder material | Stainless steel | ||

| Pot shell Material |

aluminium alloy 270*270*195mm |

aluminium alloy 270*296*240mm |

aluminium alloy 310*320*240mm |

| Pot bravery |

Stainless steel 250*140mm |

Stainless steel 255*170mm |

Stainless steel 280*170mm |

| Plate size | 280*330 | 350*330 | 350*330 |

| Evaporator flask | 2L 24# |

3L flange mouth:Φ50mm |

5L flange mouth:Φ50mm |

| Collect flask | 1L 24# | 2L 35# | 3L 35# |

| Vacuum degree | 0.098Mpa | ||

| Rotary speed | 0-120RPM | ||

| Rotary power | 30W | 40W | 40W |

| Heating power | 1.5KW | 2KW | 2KW |

| Heating temp. | 0-400C | ||

| Temp. accuracy | -1 | ||

| Lifting stroke | 120mm | ||

| Voltage | 220/110V 50/60HZ | ||

| Dimension | 700*440*885mm | 660*330*970 | 700*335*1009 |

| Packing size | 590*460*460mm | 1000*460*450 | 1040*620*410mm |

| Packing weight | 21kg | 38kg | 38kg |

| Configuration list | |||

| Speed mode | Electronic stepless | ||

| Speed Display | Digital | ||

| Temp. display | K type sensor Digital display | ||

| Temp. control | Intelligent temp.control | ||

| Sealing method | PTFE | ||

| Condenser |

Vertical 85*460mm 29# |

Vertical 100*510mm 29# |

Vertical 100*590mm 29# |

| Lifting mode | Manual lifting | ||

| Continuous feed | 19# Standard mouth feed valve | ||

| Discharge mode | --- | --- |

PTFE Discharge valve flange mouth:Φ50mm |

| Vacuum Display | Vacuum gauge | ||

NBRE-1002/NBRE-2002/NBRE-5003 10L 20L 30L

1. Using PTFE + fluorine rubber seal cover, to maintain a high vacuum degree. Gas-liquid separation, no reflow .

2. USES the main and secondary efficient double condenser to ensure high recovery rate.

3. Rotating bottle with nut connection, it is easy to load and unload.

4. There is tap valve under the collection bottle mouth, recycled solvent is very fast.

5. Feeding continuously.

6. Vacuum gauge is to make sure the best work vacuum degree can be adjusted for the low boiling point materials.

7. Water bath with digital and continuous temperature controlling.

8. Reasonable structure, special materials . The mechanical structure mainly use stainless steel and aluminum alloy parts, glass pieces are all made of high temperature resistant and high boron glass. Imported Electrical key-module. Rubber seal is easy to adopt the new international, making it easy for users to purchase and update.

| Model | NBRE-1002 | NBRE-2002 | NBRE-3002 |

| Glass meterial | GG-17 | GG-17 | GG-17 |

| Holder material | Stainless steel | Stainless steel | Stainless steel |

|

Pot shell Material |

Spray anti-corrosion 490*430*540mm |

Spray anti-corrosion 630*534*638mm |

Spray anti-corrosion 710*620*700mm |

| Pot bravery |

Stainless steel 350*220mm |

Stainless steel 450*250mm |

Stainless steel 000*280mm |

| Plate size | 474*474 | 534*504 | 804*574 |

|

Evaporator flask |

10L flange mouth:Φ95mm |

20L flange mouth:Φ95mm |

30L flange mouth:Φ125mm |

| Collect flask |

5L flange mouth:Φ50mm |

10L flange mouth:Φ60mm |

20L flange mouth:Φ60mm |

| Vacuum degree | 0.098Mpa | 0.098Mpa | 0.098Mpa |

| Rotary speed | 0-110RPM | 0-110RPM | 0-110RPM |

| Rotary power | 120W | 120W | 180W 220V/50HZ |

| Heating power | 3KW | 5KW | 8KW 380V/50HZ |

| Heating temp. | 0-400 | 0-400 | 0-400 |

| Temp. accuracy | ±1 | ±1 | ±1 |

| Lifting stroke | 180mm | 180mm | 180mm |

| Voltage | 220V/50HZ | 220V/50HZ | |

| Dimension | 970*480*1950 | 1170*540*2200 | 1520*620*2470 |

| Packing size |

1350*350*400 1280*570*660 |

1370*700*680 700*680*740 |

1450*390*440 1150*840*660 790*730*790 |

| Packing weight | 100 | 123 | 170 |

| Configuration list | |||

| Speed mode |

Frequency Control speed |

Frequency Control speed |

Frequency Control speed |

| Speed Display | digital | digital | digital |

| Temp. display |

K type sensor digital display |

K type sensor digital display |

K type sensor digital display |

| Temp. control | intelligent temp. control | intelligent temp. control | intelligent temp. control |

| Sealing method | PTFE | PTFE | PTFE |

| Condenser |

Vertical efficiency three reflux condenser Main:120*640mm Deputy:135*470mm |

Vertical efficiency three reflux condenser Main:130*680mm Deputy:160*530mm |

Vertical efficiency three reflux condenser Main:160*840mm Deputy:160*530mm |

|

Continuous collection | non-return valve control | non-return valve control | non-return valve control |

| Lifting mode | Manual lifting | Manual lifting | Manual lifting |

|

Temp. measurement methods | 19# | 19# | 19# |

|

Continuous feed |

34# Standard mouth feed valve |

34# Standard mouth feed valve |

40# Standard mouth feed valve |

|

Discharge mode |

PTFE Discharge valve flange mouth:Φ50mm |

PTFE Discharge valve flange mouth:Φ60mm |

PTFE Discharge valve flange mouth:Φ60mm |

| Vacuum Display | Vacuum gauge | Vacuum gauge | Vacuum gauge |

| Option | |||

| Lifting mode | Automatic electric lifting | ||

| Collection device | Double collect bottle | ||

| Explosion-proof | Explosion-proof motor&Explosion-proof inverter EX120W | ||

| Frame portion | Spray PTFE | ||

|

Bath pot Material | Full 304SUS | ||

50L 100L

| Model | NBRE-5003 | NBRE-100L |

| Glass meterial | GG-17 | GG-17 |

| Holder material | Stainless steel | Stainless steel |

|

Pot shell Material |

Spray anti-corrosion 710*620*700mm |

Spray anti-corrosion 820*820mm |

| Pot bravery |

Stainless steel 550*320mm |

Stainless steel 795*330mm |

| Plate size | 804*574mm | 1600*830mm |

|

Evaporator flask |

50L flange mouth:Φ125mm |

100L flange mouth:Φ180mm |

| Collect flask |

20L flange mouth:Φ60mm |

50L ball mouth:Φ40mm |

| Vacuum degree | 0.098Mpa | 0.098Mpa |

| Rotary speed | 0-110RPM | 0-110RPM |

| Rotary power | 180W 220V/50HZ | 400W 220V/50HZ |

| Heating power | 8KW 380V/50HZ | 12KW 380V/50HZ |

| Heating temp. | 0-400 | 0-400 |

| Temp. accuracy | ±1 | ±1 |

| Lifting stroke | 180mm | 180mm |

| Voltage | ||

| Dimension | 1520*620*2470 | 1700*850*2600 |

| Packing size |

1450*390*440mm 1150*840*660mm 790*730*790mm | |

| Packing weight | 170kg | 400 |

| Speed mode |

Frequency Control speed |

Frequency Control speed |

| Speed Display | digital | LCD |

| Temp. display |

K type sensor digital display |

K type sensor digital display |

| Temp. control | intelligent temp. control | intelligent temp. control |

| Sealing method | PTFE | PTFE |

| Condenser |

Vertical efficiency three reflux condenser Main:160*840mm Deputy:160*530mm |

Vertical efficiency three reflux condenser Main:230*950mm Deputy:230*530mm |

|

Continuous collection | non-return valve control | non-return valve control |

| Lifting mode | Manual lifting | Automatic lifting |

|

Temp. measurement methods | 19# | |

|

Continuous feed |

40# Standard mouth feed valve |

29# Standard mouth feed valve |

|

Discharge mode |

PTFE Discharge valve flange mouth:Φ60mm |

PTFE Discharge valve flange mouth:Φ60mm |

| Vacuum Display | Vacuum gauge | Vacuum gauge |

NEW 10L 20L 30L

Brief introduction :

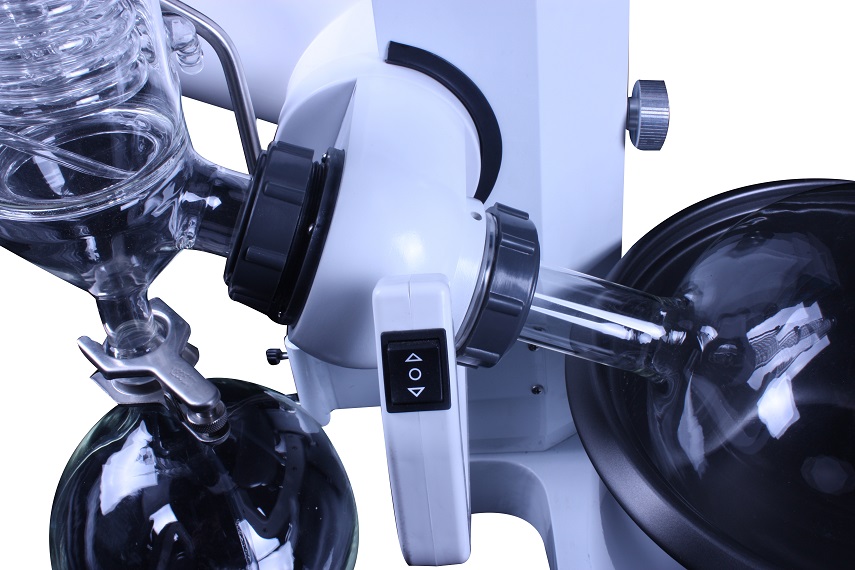

Rotary evaporator use stepless speed to make the glass rotating bottle constant rotation, the material in the bottle wall to form a large area of uniform film, and then through the intelligent constant temperature water bath heat the rotating bottle uniformly, high-speed evaporation under vacuum case, after the efficient glass condenser cooling, the solvent vapor will recycle in the collection bottle.

Features of Rotary evaporator:

• The main bracket is made of stainless steel and aluminum alloy with reasonable structure and materials.

• All glass components are borosilicate glass (GG-17), high temperature, anti-corrosion.

• Sealing system adopts imported fluorine rubber and Teflon two-way combination seal, long corrosion-resistant life, to maintain a high degree of vacuum.

• Vacuum gauges show real-time vacuum, oil-based table with anti-vibration characteristics.

• Upright three-layer serpentine coil condenser, main cooler + double cooler, ensuring high recovery.

• Continuous feeding for customer's convenience, valve type feeding valve socket PTFE tube.

• Collecting bottles are equipped with dropping materials to facilitate the collection and discharge of evaporated extracts.

• Check valve control, continuous discharge, the machine in working condition, the vacuum switch.

• All valves use the latest integrated hand wheel valve, sealing is good, the operation is more simple and convenient

Microprocessor-based power switch control.

• LCD full screen display, temperature, speed dual digital display, bath thermostat intelligent control, PT100-type sensor, quickly and accurately transfer temperature.

• Brushless DC motor, stable rotation, no spark, slow down by force.

• Bath electric lift, lift part of the deceleration by force motor, lifting process more stable.

• The pot is made of high-quality 304 stainless steel, corrosion-resistant and durable. The outer layer of the pot is covered with a silicone layer, which makes it safer to use at high temperature.

• Over-temperature protection function, when the actual temperature exceeds the set temperature of 5 ℃, the machine will automatically power-off heating.

• Anti-dry function, the heating pot lower than the heating pipe, the machine will automatically power off.

• If there is a sudden power failure while the machine is working, the machine will stop heating automatically when the power is turned on again.

10L

| Power supply | 220V/50HZ (various power supply and plug can be customized) |

| Rotating motor power | 60W |

| Lifting motor power | 40W |

| Heating power | 4.5KW |

| Vacuum degree | 0.098Mpa |

| Rotating flask capacity | 10000ml Φ280mm/Φ95mm flange mouth |

| Collecting flask capacity | 5000ml Φ230mm/Φ50mm flange mouth |

| Rotating speed | 0-120rpm/min |

| Temperature controlling range | 0-400℃ |

| Temperature controlling accuracy | ±1℃ |

| Glass temperature range | -80-250℃ |

| Lifting stroke | 0-180(mm) |

| Condenser size | MainΦ130×640H(mm) DeputyΦ130×410H(mm) |

| Feed valve | Φ35 flange mouth |

| Release valve | Φ35 flange mouth*2pcs |

| Discharge valve | ¢10mmglass and lean discharge port |

| Bath size/volume | Φ350×220H(mm) about21L |

| Dimension | 1100*400*1900(mm) |

| Packing size | 1070L×520W×1210H(mm) about0.67m3 |

| Gross weight | 95KG |

20L

| Power supply | 220V/50HZ (various power supply and plug can be customized) |

| Rotating motor power | 60W |

| Lifting motor power | 40W |

| Heating power | 5KW |

| Vacuum degree | 0.098Mpa |

| Rotating flask capacity | 20000ml Φ355mm/Φ95mm flange mouth |

| Collecting flask capacity | 10000ml Φ280mm/Φ60mm flange mouth |

| Rotating speed | 0-120rpm/min |

| Temperature controlling range | 0-400℃ |

| Temperature controlling accuracy | ±1℃ |

| Glass temperature range | -80-250℃ |

| Lifting stroke | 0-180(mm) |

| Condenser size | MainΦ130×680H(mm) DeputyΦ130×410H(mm) |

| Feed valve | Φ35 flange mouth |

| Release valve | Φ35 flange mouth*2pcs |

| Discharge valve | ¢10mmglass and lean discharge port |

| Bath size/volume | Φ450×250H(mm) about39L |

| Dimension | 1200*500*2000(mm) |

| Packing size | 1070L×520W×1210H(mm) about0.67m3 |

| Gross weight | 102KG |

50L

| Power supply | 380V/50HZ (various power supply and plug can be customized) |

| Rotating motor power | 100W |

| Lifting motor power | 60W |

| Heating power | 8KW |

| Vacuum degree | 0.098Mpa |

| Rotating flask capacity | 50000ml Φ470mm/Φ125mm flange mouth |

| Collecting flask capacity | 20000ml Φ355mm/Φ60mm flange mouth |

| Rotating speed | 0-120rpm/min |

| Temperature controlling range | 0-400℃ |

| Temperature controlling accuracy | ±1℃ |

| Glass temperature range | -80-250℃ |

| Lifting stroke | 0-180(mm) |

| Condenser size | MainΦ160×840H(mm) DeputyΦ160×480H(mm) |

| Feed valve | Φ35 flange mouth |

| Release valve | Φ35 flange mouth*2pcs |

| Discharge valve | ¢15mmglass and lean discharge port |

| Bath size/volume | Φ550×320H(mm) about76L |

| Dimension | 1400*600*2250(mm) |

| Packing size | 1270L×620W×1440H(mm) about1.133m3 |

| Gross weight | 118KG |